Centrifuge

High-temperature zinc plating with centrifugation is currently the best and most effective method for corrosion protection. Resistant to mechanical damage, protect the material exposed to high loads. Melting to a temperature of 600 degrees causes the zinc to spread perfectly on the details.

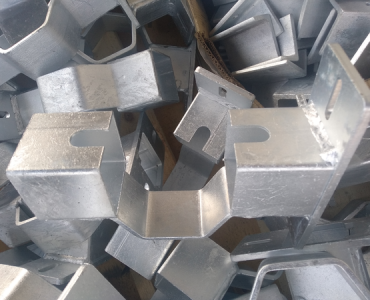

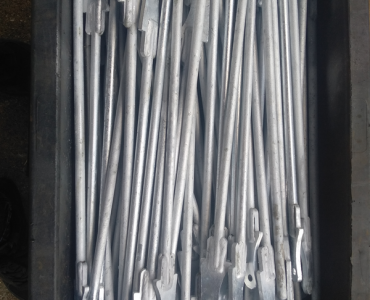

FAM Sp. z o.o. The Oborniki plant has a technological line dedicated to hot dip galvanizing of small elements with centrifugation, such as: connectors, hooks, nails, screws, nuts, forgings, small steel constructions. This technology is also ideal for protecting the surfaces of cast iron and steel industrial fittings against atmospheric corrosion.

For small products, hanging is not advisable due to high labour-consumption when hanging on wires or hooks, the possibility of detachment of elements in galvanizing baths, the deteriorated aesthetics of the coating and increased zinc consumption due to the occurrence of runs and overflows of zinc alloy. All of the above problems can be avoided by using a galvanizing technique where the components are placed in a basket and centrifuged after being drawn out of the zinc bath. By maintaining the appropriate parameters of the galvanizing process, it is also possible to maintain the metallic gloss of the product surface that is so attractive to customers.

The process can be carried out at low or high temperatures depending on the Customer’s requirements. The production capacity of the galvanizing line for small and medium-sized steel products is 700 kg/h, and temporarily even up to 1000 kg/h.

On the technological line for hot-dip galvanizing of small elements FAM Sp. z o.o. implements a technology, unique on a European scale, for producing zinc-aluminium coating, which in the future, thanks to better functional properties and higher surface aesthetics, may replace the zinc coating in many applications. The pilot line was designed and constructed as part of the project: “Demonstration of a highly automated technological line for the application of hot-dip zinc and zinc-aluminium coatings on small and medium-sized steel components”, co-financed with EU funds under the Operational Programme Intelligent Development 2014-2020, Priority Axis: Support for conducting R&D works by enterprises, Measure: Business R&D projects.

Our offer

- attractive prices

- short lead times

- high quality

- possibility of galvanizing small elements in large series

- no overflows, icicles or flooding of threads

- innovation (possibility of zinc-aluminium coating)